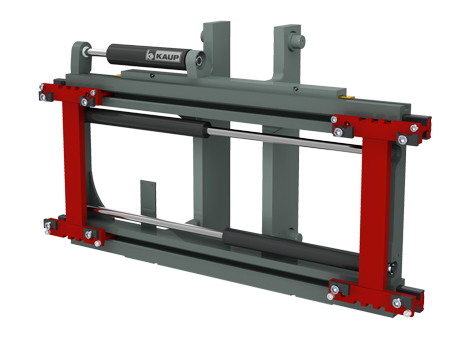

T466BI Fork Positioner

with independent sideshift - without forks - for forks acc. to ISO 2330 - 2 hydraulic functions

The KAUP integrated Fork Positioner T466BI has been specially designed with optimised visibility and residual capacity. The attachment is manufactured from proven components and is suitable for moderately heavy duty tasks. Fork Positioners are particularly effective when different sizes of loads are regularly transported or different kinds of transportation is used.

- For moderately heavy operation - complete program with capacities of up to 10 tons

- Very good residual capacity

- Excellent visibility

- Supplied with welded forks

- Supplied optionally with screw on forks for wear intensive operation (A-version)

- Independent sideshift serially

| Model | Cap. kg | LCD mm | A mm | A1 mm | A2 mm | B mm | C mm | S mm | mm | ISO | V mm | CofG Z mm | CofG Y mm | Weight kg | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2T466BI | 2.500 | 500 | 150-850 | 250-950 | 320-1.020 | 1.040 | 240 | ±100 | 120 | 2 | 133 | 58 | 218 | 156 | |

| 2T466BI | 2.500 | 500 | 150-950 | 250-1.050 | 320-1.120 | 1.150 | 240 | ±100 | 120 | 2 | 133 | 58 | 217 | 163 | |

| 2,5T466BI | 2.500 | 600 | 150-850 | 250-950 | 320-1.020 | 1.040 | 240 | ±100 | 120 | 2 | 133 | 60 | 218 | 158 | |

| 2,5T466BI | 2.500 | 600 | 150-950 | 250-1.050 | 320-1.120 | 1.150 | 240 | ±100 | 120 | 2 | 133 | 60 | 217 | 165 | |

| 3,5T466BI | 3.500 | 500 | 180-980 | 250-1.050 | 320-1.120 | 1.150 | 240 | ±100 | 130 | 3 | 138 | 60 | 262 | 177 | |

| 3,5T466BI | 3.500 | 500 | 180-1.180 | 250-1.250 | 320-1.320 | 1.350 | 240 | ±100 | 130 | 3 | 138 | 62 | 262 | 190 | |

| 4,8T466BI | 5.000 | 600 | 180-1.180 | 250-1.250 | 320-1.320 | 1.350 | 255 | ±100 | 150 | 3 | 148 | 65 | 268 | 279 | |

| 4,8T466BI | 5.000 | 600 | 180-1.360 | 250-1.430 | 320-1.500 | 1.550 | 255 | ±100 | 150 | 3 | 148 | 62 | 266 | 319 | |

| 6T466BI | 6.000 | 600 | 260-1.170 | 350-1.260 | 440-1.350 | 1.460 | 330 | ±100 | 150 | 4 | 171 | 68 | 343 | 402 | |

| 6T466BI | 6.000 | 600 | 260-1.360 | 350-1.450 | 440-1.540 | 1.650 | 330 | ±160 | 150 | 4 | 171 | 68 | 345 | 435 | |

| 6T466BI | 6.000 | 600 | 260-1.560 | 350-1.650 | 440-1.740 | 1.860 | 330 | ±160 | 150 | 4 | 171 | 68 | 343 | 468 | |

| 8T466BI | 8.000 | 600 | 260-1.560 | 350-1.650 | 440-1.740 | 1.860 | 330 | ±160 | 150 | 4 | 171 | 68 | 343 | 468 | |

| 8T466BI | 8.000 | 600 | 260-1.760 | 350-1.850 | 440-1.940 | 2.060 | 330 | ±160 | 150 | 4 | 171 | 65 | 341 | 523 | |

| 8T466BI | 8.000 | 600 | 260-1.960 | 350-2.050 | 440-2.140 | 2.260 | 330 | ±160 | 150 | 4 | 171 | 65 | 340 | 559 | |

| 8T466BI | 8.000 | 600 | 260-2.060 | 350-2.150 | 440-2.240 | 2.400 | 330 | ±160 | 150 | 4 | 171 | 64 | 340 | 586 | |

| 10T466BI | 8.000 | 1.100 | 260-1.760 | 360-1.860 | 460-1.960 | 2.060 | 370 | ±160 | 200 | 4 | 234 | 102 | 344 | 880 | |

| 10T466BI | 8.000 | 1.100 | 260-1.960 | 360-2.060 | 460-2.160 | 2.260 | 370 | ±160 | 200 | 4 | 234 | 101 | 343 | 940 | |

| 10T466BI | 8.000 | 1.100 | 260-2.060 | 360-2.160 | 460-2.260 | 2.400 | 370 | ±160 | 200 | 4 | 234 | 100 | 342 | 978 |

with independent sideshift - without forks - for forks acc. to ISO 2330 - 2 hydraulic functions

with independent sideshift - without forks - for forks acc. to ISO 2330 - 2 hydraulic functions

with valveblock sideshift dependent on the opening range - without forks - for forks acc. to ISO 2330, 2 hydraulic function

with valveblock sideshift dependent on the opening range - without forks - for forks acc. to ISO 2330 - 2 hydraulic functions

with valveblock sideshift dependent on the opening range - without forks, for forks with quick release system 'Terminal West' - 2 hydraulic functions

with valveblock sideshift dependent on the opening range - 2 hydraulic functions

with valveblock sideshift dependent on the opening range - 2 hydraulic functions

with independent sideshift - without forks - for forks acc. to ISO 2330 - 2 hydraulic functions

with independent sideshift - 2 hydraulic functions

with independent sideshift - 2 hydraulic functions

without sideshift - 1 hydraulic function

with independent sideshift, 2 hydraulic functions - without forks - for forks acc. to ISO 2330

with independent sideshift - 2 hydraulic functions

with valveblock sideshift dependent on the opening range - 2 hydraulic functions

with valveblock sideshift dependent on the opening range - 2 hydraulic functions

with independent sideshift - 2 hydraulic functions

Rotation 360° continuous - 2 hydraulic functions

Rotation 360° continuous - 2 hydraulic functions

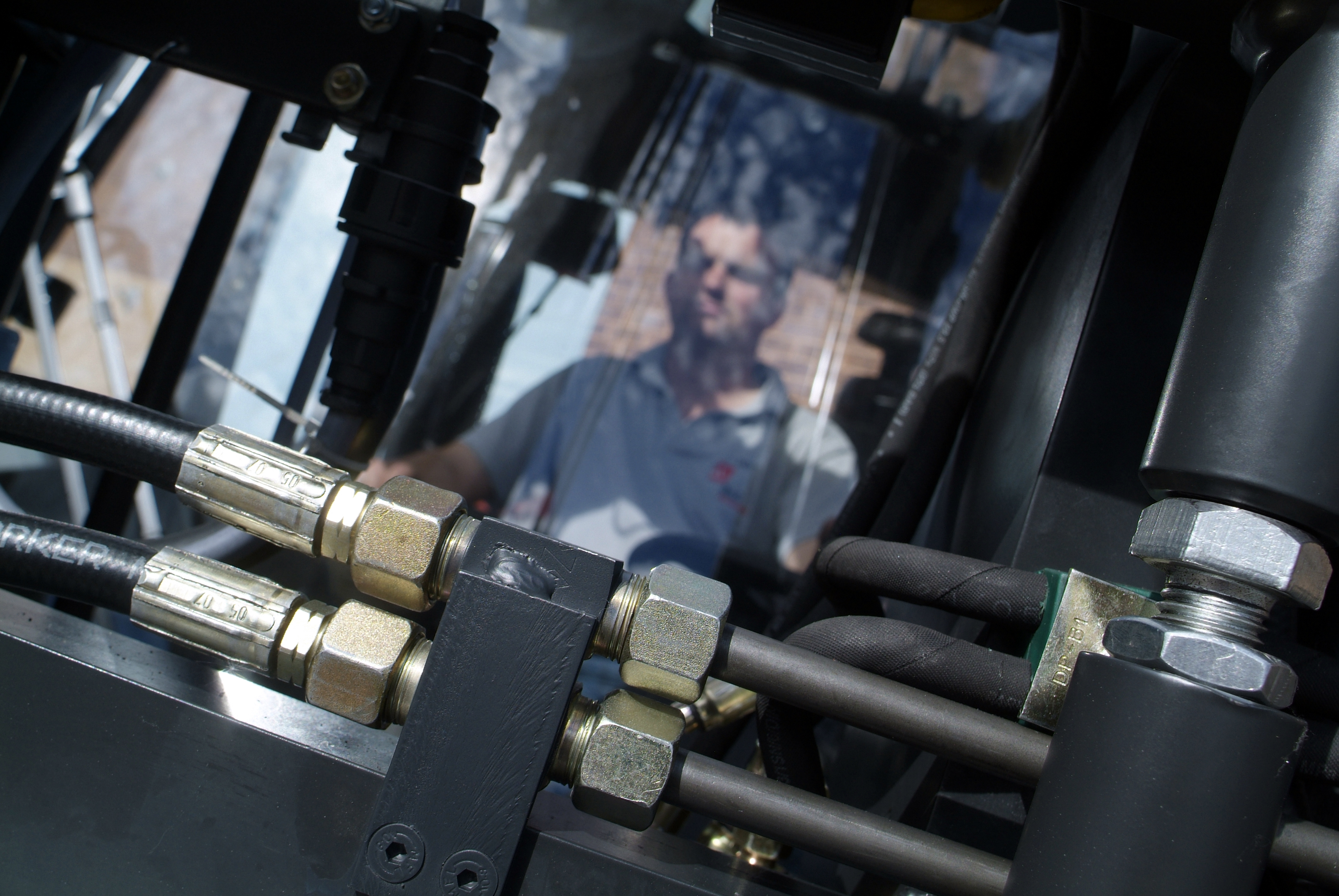

Spare Parts

An extensive parts holding and efficient Parts Department is the key to the success of any maintenance operation. At our Cramlington facility, B&B maintains the highest viable spares and parts inventory, constantly reviewed and replenished from the original equipment manufacturers in the UK, Finland, Italy and Germany.

Field Service

With our team of qualified, experienced, factory-trained field service engineers with fully equipped vans based strategically throughout the UK, B&B is here to help you ensure that your new equipment is installed and maintained and any equipment failure and associated costly downtime are kept to an absolute minimum.

Workshop

B&B offers a complete refurbishment service - from minor repairs to total factory rebuilds of your existing fork lift truck attachments.

Kaup Fork Positioners

Kaup Fork Positioners