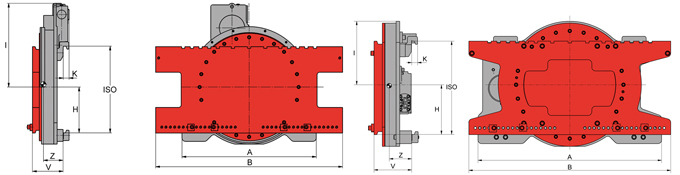

T351G Rotator

1 hydraulic function

The KAUP Rotator 360° T351 is also available in a foundry version. This attachment is adapted to the demands of this operational with a closed fork carriage plate and a closed base plate as well as heat-resistant covered hydraulic tubes.

This attachment is fundamental for onsite operations when loads require rotating, and is used to empty containers, to turn palletised and non-palletised goods, and to deal with waste. Rotators can be equipped with a fork carriage and forks, as well as with clamps or other load handling attachments.

Kaup Rotators allow for optimal visibility when approaching loads, whilst increasing driver confidence and ensuring safe and secure handling. The hydraulic drive is located on the side away from the operator resulting in excellent visibility, enabling fast and reliable operation.

- Foundry implementation

- Good residual capacity

- Rotation 360° endlessly

- Robust construction with gear drive

- Original forks usableLateral supporting fork and load stabilizers optionally

| Model | Cap. kg | LCD mm | A mm | B mm | H mm | I mm | K mm | ISO | Md ∆-P = 125 bar Nm | Req.oil volume per rotation ltr. | V mm | CofG Z mm | Weight kg | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1T351.2G | 1.800 | 500 | 817 | 890 | 203 | 288 | 33 | 2 | 6.013 | 7,6 | 207 | 124 | 250 | |

| 2T351.1G | 2.500 | 500 | 790 | 1.040 | 269 | 515 | 29 | 2 | 7.700 | 9,7 | 174 | 93 | 302 | |

| 2T351.1G | 2.500 | 500 | 790 | 1.150 | 269 | 515 | 29 | 2 | 7.700 | 9,7 | 174 | 95 | 310 | |

| 2,5T351.1G | 3.200 | 500 | 790 | 1.100 | 269 | 515 | 33 | 3 | 7.700 | 9,7 | 179 | 106 | 387 | |

| 3,5T351.1G | 4.000 | 500 | 880 | 1.100 | 381 | 539 | 36 | 3 | 11.815 | 13,8 | 202 | 113 | 525 | |

| 4T351.1G | 5.000 | 500 | 900 | 1.100 | 378 | 595 | 36 | 3 | 14.823 | 17,4 | 221 | 120 | 575 | |

| 4,5T351.1G | 5.000 | 500 | 900 | 1.350 | 328 | 695 | 40 | 4 | 14.823 | 17,4 | 231 | 129 | 670 | |

| 5T351.2G | 6.000 | 600 | 1.260 | 1.350 | 345 | 455 | 40 | 4 | 13.434 | 15,7 | 275 | 163 | 780 | |

| 6T351.2G | 6.500 | 600 | 1.260 | 1.350 | 345 | 455 | 40 | 4 | 17.157 | 20,7 | 275 | 157 | 831 | |

| 8T351.2G | 8.000 | 900 | 1.300 | 1.600 | 396 | 480 | 40 | 4 | 21.679 | 18,8 | 304 | 175 | 1.080 |

1 hydraulic function

1 hydraulic function

with independent sideshift - 2 hydraulic functions

with independent sideshift - 2 hydraulic functions

with independent sideshift - 2 hydraulic functions

1 hydraulic function

with independent sideshift - tilt angle a = 100° to the right side in driving direction - 2 hydraulic functions

2 hydraulic function, To empty ladles to both sides and forwards.

Spare Parts

An extensive parts holding and efficient Parts Department is the key to the success of any maintenance operation. At our Cramlington facility, B&B maintains the highest viable spares and parts inventory, constantly reviewed and replenished from the original equipment manufacturers in the UK, Finland, Italy and Germany.

Field Service

With our team of qualified, experienced, factory-trained field service engineers with fully equipped vans based strategically throughout the UK, B&B is here to help you ensure that your new equipment is installed and maintained and any equipment failure and associated costly downtime are kept to an absolute minimum.

Workshop

B&B offers a complete refurbishment service - from minor repairs to total factory rebuilds of your existing fork lift truck attachments.

Kaup Rotators - Ladle Tippers

Kaup Rotators - Ladle Tippers